Electro Magnetic Inspection (EMI) Services for Casing & Tubing

What is EMI?

Advantages of EMI

- Detect Defects: One of the primary benefits of EMI is its ability to detect defects and abnormalities at an early stage, often before they become critical issues.

- Prevent Costly Failures: This proactive approach prevents costly downtime and safeguards your investment in tubular assets.

DWT's EMI Expertise

- Expertise: At Deep Well Tubular Service, our track record speaks volumes since industry leaders trust us for our never-back-down dedication to EMI excellence.

- Team: Our team brings a blend of technical proficiency and industry insight to ensure that every inspection we perform meets the highest standards of accuracy and reliability.

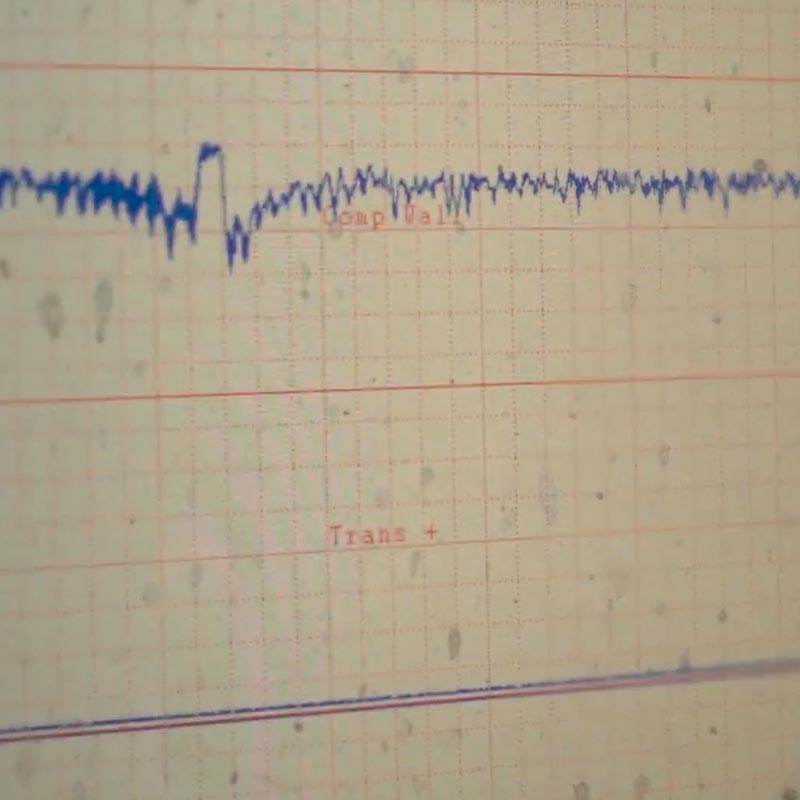

EMI Process

- Electromagnetic Inspection: First, the tubular undergoes electromagnetic inspection when our advanced EMI technology scans its internal and external surfaces to collect data that includes wall thickness, defects, and other abnormalities.

- Data Analysis: Then our team interprets the results by identifying any potential issues or areas of concern, and this in-depth analysis allows us to detect defects.

- Reporting: Following the analysis, we complete a detailed report with your tubular's condition that includes our findings, recommendations. and a clear integrity assessment - a valuable tool for making informed decisions about maintenance and future operations.

Quality Control Measures

- Quality Checks: At DWTS, quality is important - so to ensure the reliability and accuracy of our EMI inspections, we implement strict quality control measures.

- Calibration: Our EMI equipment undergoes regular calibration to guarantee consistency.

- Continuous Improvement: We consistently review and enhance our quality control procedures to stay with industry standards and deliver the most dependable EMI services.

Why Choose Deep Well Tubular Service?

Extensive Experience in the Oil & Gas Sector

At Deep Well Tubular Services, our team brings a wealth of experience where we deeply understand the unique challenges and demands of the oil & gas industry. Founded by Bob Herrel in 1980 and renamed "Deep Well Tubular Services" in 1989 - sustaining 44 years of superior OCTG industry service! Our track record includes serving numerous clients throughout West Texas and beyond the Permian Basin.

Safety Protocols

We prioritize the safety of our team members and your project. Our team adheres to strict safety protocols and undergoes regular training to ensure that operations are conducted safely and efficiently. We are committed to preventing accidents and providing a secure work environment.

Quality Assurance

Our quality at Deep Well Tubular Services is non-negotiable! We have quality assurance procedures to confirm the integrity of our work from the initial design to the final product.

Choosing DWTS means partnering with a team that combines extensive industry experience and an unwavering commitment to safety and quality. We are dedicated to delivering solutions that meet your expectations and contribute to the success and longevity of your oil & gas operations.

Proven Expertise

Our experienced professionals have decades of knowledge in the OCTG industry - Recognizing the critical role of casing and tubing in the safe and efficient extraction of hydrocarbons.

Contact Us Today

Discover how Deep Well Tubular Services can meet your needs with precision and expertise. Contact us today for customized solutions and a free consultation. Your success is our priority!